Real-Time Testing

Python-based real-time test automation

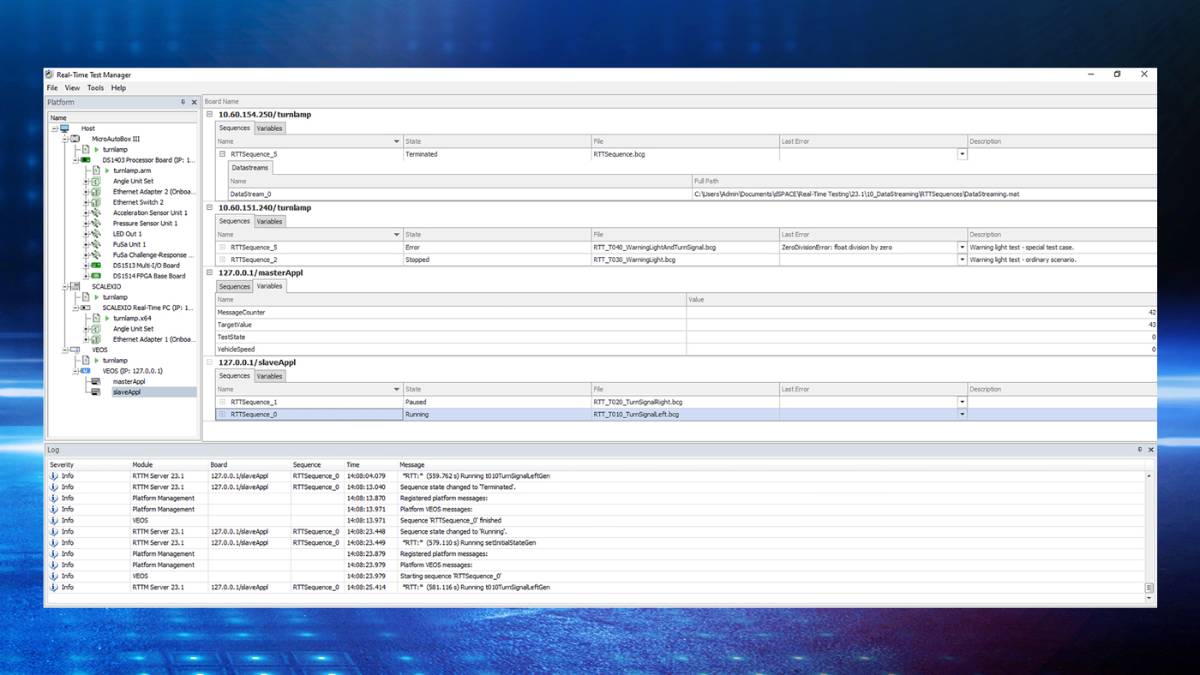

Python-based test automation – 100% reproducible real-time tests executed synchronously with simulation model

- Real-time testing (RTT) without model modification

- Easy integration into user-defined test frameworks (AutomationDesk or others)

- Support of all dSPACE platforms1) including VEOS

1) Except DS1104.

Application Areas

Automated testing is usually performed by executing tests on a standard PC connected to the hardware-in-the-loop (HIL) system. However, this method often cannot cope where greater timing precision is required – for example, if ECU interaction has to be captured and responded to in a range of milliseconds. Real-Time Testing (RTT) with its Python scripts for real-time testing is the answer.

Key Benefits

The scripts run on the simulation platform, e.g., a dSPACE HIL system. They run synchronously with the model, so all test actions are performed on a real-time basis – 100% reproducibly. This opens up expanded test options with dSPACE Simulator. Reactive tests which respond to changes in model variables within the same simulation step can be implemented. Time measurements in tests are also far more precise, as there are no latencies in communication. Simulation step size is now the only limit to the maximum time resolution of measurements. Real-time test scripts do not only run on HIL systems but also on VEOS, dSPACE's platform for PC-based offline simulation. Therefore, you can reuse the test scripts seamlessly throughout the entire development process – from virtual validation to HIL simulation.

| Features | Description | Benefits |

| 100% reproducible RTT tests |

|

|

| RTT tests without model changes |

|

|

| Easy to implement |

|

|

| Python Interpreter on the simulation platform |

|

|

| RTT scripts ideally suited for GIT |

|

|

| Reading and writing model variables |

|

|

| Data streaming |

|

|

| CAN and ETHERNET access |

|

|

| Platform support |

|

|

Certified according to ISO 26262

For validating ECU software, dSPACE offers several tools that are certified according to ISO 26262. These include Real-Time Testing (RTT), SIMPHERA, VEOS and the Platform API Package. This means that all these products can be used in safety-relevant development projects in accordance with ISO 26262:2018 for all Automotive Safety Integrity Levels (ASIL).

The certification enables users to simplify their overall ISO 26262 processes. They can use the tools in safety-critical projects with very little qualification effort and are provided with safety manuals to support them in their use case.

Drive innovation forward. Always on the pulse of technology development.

Subscribe to our expert knowledge. Learn from our successful project examples. Keep up to date on simulation and validation. Subscribe to/manage dSPACE direct and aerospace & defense now.