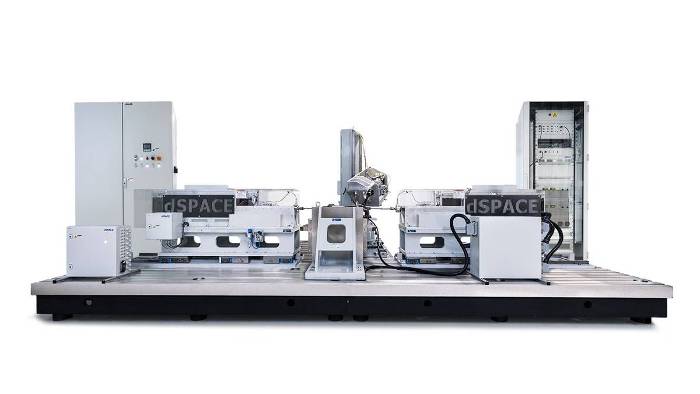

To develop new chassis control strategies, Brilliance has built a laboratory setup that consists of a combination of a dSPACE steering and brake system test bench.

During the development and testing of new chassis control strategies, a large number of components must be taken into account. This includes the brake and steering systems, for example, which play an important role among the vehicle safety systems because they contain a number of electrical and electronic components and make the driving status directly accessible for the driver. Therefore, Brilliance has set up a development environment for functions for chassis control that includes a steering and a brake system test bench from dSPACE. With this setup, Brilliance can perform comprehensive tests to ensure that all functions for chassis control work reliably.

Test Challenges

At Brilliance, the development process is divided into several stages. During each stage, certain hardware and software components are provided by external suppliers. The electronic stability program (ESP) and electric power steering (EPS) systems are also supplied by external sources, and two different ones at that. This is why Brilliance engineers perform both component tests and integration tests to rule out any system inconsistencies. Specific tests were performed, for example, for lane change, slalom, traction control system (TCS), vehicle dynamics control (VDC), antilock braking system (ABS), and hill hold control (HHC).

dSPACE System for Managing Test Variety

The dSPACE system was purchased to save time and reduce the cost of testing while tackling the above-mentioned challenges. In addition, Brilliance also wants to frontload the tests to the early stages of development to detect possible errors as early as possible and thus ultimately increase the technical maturity of the products. In addition, the company wants to easily verify the controllers provided by suppliers via black-box testing, i.e., testing them exactly in the condition in which they are provided to Brilliance. This saves Brilliance the effort of accessing the inner workings of the controllers via interfaces that would first have to be created.

Launched in June 2018, the Brilliance V7 SUV was the first vehicle that Brilliance developed using the dSPACE test bench. More models are already in development.

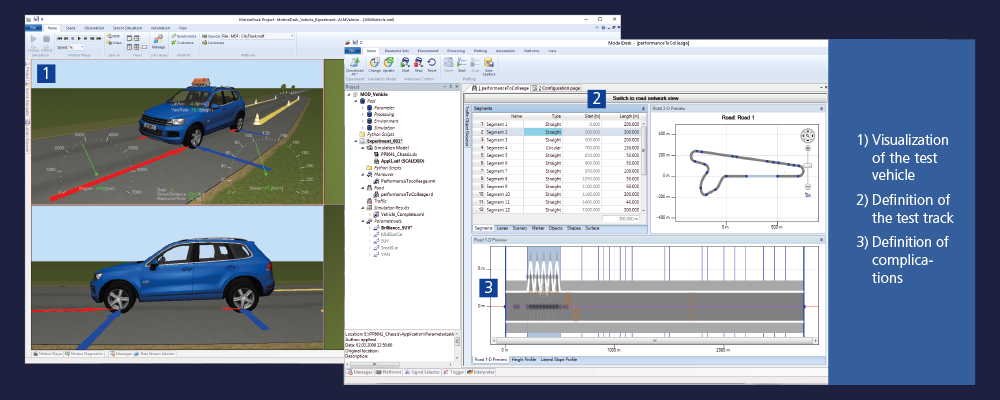

Setup of the Test Bench

The dSPACE SCALEXIO simulator, which provides the required processor power, input and output interfaces, and signal conditioning, is used to control the test bench motors. The simulator also records all measurement data. The experiment and instrumentation software dSPACE ControlDesk is used to control the entire test bench for setting, monitoring, and graphically displaying parameters, for example. The dSPACE test automation software dSPACE AutomationDesk also plays an important role for testing, because it can be used to automate all test sequences, even for overnight tests. Vehicle dynamics are simulated in real time using the dSPACE Automotive Simulation Models (ASM) tool suite. The graphical user interface of dSPACE ModelDesk is used for convenient parameterization of the vehicle models. Using this development environment, the engineers at Brilliance have created dozens of driving maneuvers and road courses for their experiments. The 3-D animation software dSPACE MotionDesk displays all test drives, allowing for a rapid evaluation and modification of the driving maneuvers.

For the development of chassis control functionalities, the dSPACE setup enables comprehensive, accurately reproducible, automated tests of a wide range of driving scenarios

On the left is a typical 3-D animation with MotionDesk, and on the right is the ModelDesk user interface for parameterizing the road tests.

Testing Critical Driving Situations

A great strength of the dSPACE system is its ability to perform tests under clearly defined and reproducible conditions in the laboratory as if they were executed with a vehicle on the road. This work method allows for an exact analysis of very special and critical driving situations, the reproducible execution of which is either dangerous or even impossible in road tests in most cases. In addition, the engineers can insert specific errors on the test bench, for example, to simulate a technical defect in components to analyze and optimize the system response. In summary, the company is able to achieve a very high level of test coverage before a prototype vehicle has undergone its first test drive. The various possibilities of the test bench make tests much easier and at the same time very efficient.

Quick Familiarization

In addition to the ease of use and time saved by the dSPACE system in completing the many tasks involved in tests, another outstanding feature is the short familiarization period. The Brilliance engineers required the support of dSPACE staff only during the initial phase. After only a few weeks, the engineers at Brilliance were able to use the system to work independently and extremely productively on various projects.

More Projects Planned

The dSPACE landscape for chassis control development based on the dSPACE steering test bench and various dSPACE software tools has been in use at Brilliance for some time, and has been very helpful in testing the Brilliance V7 SUV (figure 1) as well as launching it on the market in June 2018. Based on the positive experience, the dSPACE development environment is already being used for other projects, and various enhancements are also planned.

About Brilliance

About Brilliance Brilliance China Automotive Holdings Ltd. is an investment holding company that consists of two business areas: Manufacture and sales of minibuses and automotive components as well as manufacture and sales of BMW vehicles. The company’s most important operating subsidiary in China is Shenyang Brilliance Jinbei Automobile Co, Ltd, which accounts for around 90% of sales. The company is also involved in constructing and converting minibuses and limousines as well as providing financing services through its subsidiaries.