Stationary energy storage systems are key to the successful transition to environmentally friendly energy concepts as they allow us to use the fluctuating output of renewable energy sources as efficiently as possible. The most promising storage solution in the power supply sector are stationary battery storage systems. However, hydrogen technologies such as fuel cells and electrolysis systems are also becoming increasingly important and are a valuable addition to battery storage systems, especially for the sustainable and long-term storage of energy. You can rely on our full support when developing and testing state-of-the-art battery and hydrogen technologies.

Challenges

Like battery-electric vehicles, stationary battery storage systems require a battery management system (BMS) to ensure safe, reliable and long-lasting operation of the individual battery cells. Developing hydrogen systems requires knowledge of the generation process of hydrogen, the storage system, and the conversion of hydrogen to electrical energy. For the latter, fuel cell systems are used, which require a controller to control the operation of the complete system and its individual subsystems.

Energy storage systems for renewable energies are usually large and highly complex, resulting in special requirements for their control units in terms of performance, safety, reliability, and fault tolerance. Controllers thus have to pass extensive tests before they are ready for the market. This requires powerful, reliable test systems that process the actuations and continuously provide the controller with sensor values from the energy storage system. Plant models of the systems and, if necessary, also of their environment must offer high computing power (real-time capability), scalability, and model accuracy.

dSPACE Solutions for Energy Storage Systems

We offer the right tools to help you improve your development process of controllers in the field of energy storage systems and related technologies. In case of battery systems, we provide various software and hardware products that let you test cell supervision circuits (CSCs), which monitor and balance voltages at the cell level, or even complete BMSs on the signal level and on the high-voltage level. Earlier in the development process, our solutions can support you, e.g., in prototyping BMS functions or in generating highly efficient production code for BMSs to allow for the early verification of BMS algorithms.

For fuel cell systems, our industry-proven HIL test systems, e.g., based on SCALEXIO technology, include simulators that perform all relevant functions for fuel cell ECU operation. Our ASM portfolio offers suitable fuel cell system models and test environments that can be extended in engineering projects to ensure that you meet all challenges related to the required plant models.

Simulation Modeling

Rapid Prototyping

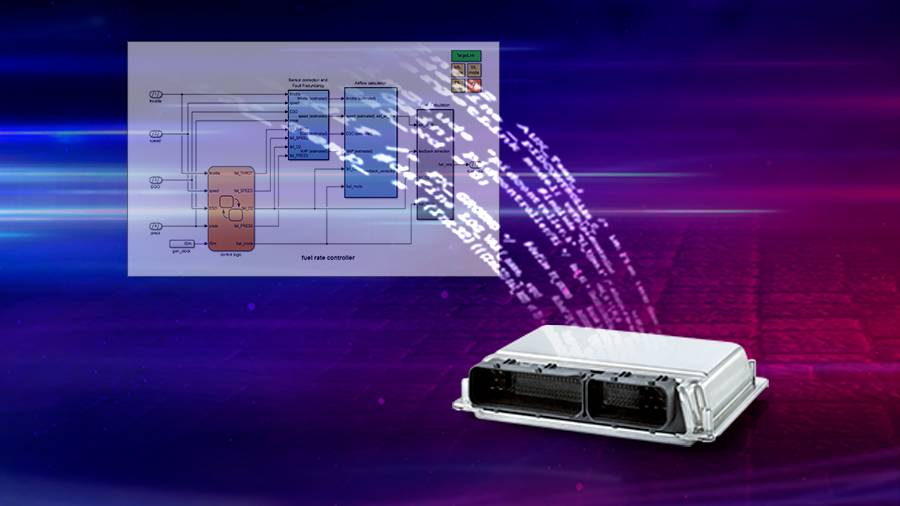

Production Software Development

Optimized Production Software Development

The central challenges in production software development include the optimization of RAM resources, run time, and integration into the overall system. Furthermore, it must be possible to split the software in such a way that regular software updates are possible. And before the final software release, special validation and often a release process are required.

SIL Testing

Software-in-the loop (SIL) testing with the powerful dSPACE solution for PC- and cloud-based simulation

With the dSPACE solution for software-in-the loop (SIL) testing, you can significantly accelerate your software development process by testing and validating virtually. dSPACE offers you a complete, modular, scalable development and test solution. You can conveniently simulate a device-under-test on a PC, connect it to physics-based models, run scalable tests in the cloud, and then easily reuse test scripts on hardware-in-the-loop (HIL) systems.

HIL Testing

Central Test Method for Validating ECUs

The dSPACE HIL test systems provide a simulated environment for efficient and reproducible validation of real ECUs in the laboratory 24/7. This increases test coverage and shortens validation times significantly. Our HIL solutions cover all vehicle domains from autonomous driving to zero emissions – starting with component testing and up to virtual vehicle testing.

Power HIL Testing

Closing the Gap Between HIL and Dynamometer Testing

With our power HIL systems, we offer ready-to-use solutions for testing any kind of inverter, including the controller and power electronics, at full power. Using real voltages and currents, our systems enable you to complete exceptionally rigorous tests. Our systems behave like a digital twin of the real system and allow for easy configuration with just a few clicks, which significantly reduces setup times.

Bus & Network Communication

Simulation, Logging, Replay, and Analysis

dSPACE provides a comprehensive and complete tool chain for simulation, analyzation, and validation, supporting a wide range of bus systems and applications. Ready-to-use products and customer-specific solutions support you during your development process.

For data exchange with any industrial devices and SCADA systems using protocols like Modbus, Distributed Network Protocol 3 (DNP3), and IEC 61850, please contact us.

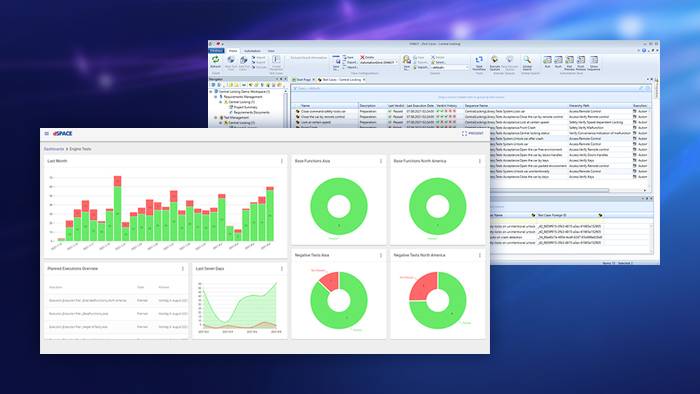

Test Data Management

Data Management and Collaboration Software for Automated ECU Testing

SYNECT, our solution for the efficient and automated verification and validation of ECU software, helps engineers worldwide handle all test parameters, their dependencies, versions and variants, and the underlying requirements throughout the entire development process.

This results in consistent data versions and complete traceability as required in homologation processes, and an efficient reuse of data in other projects.

Development support from start to finish

Developing complex E/E systems and software with ever more safety-critical functions, especially in the area of autonomous systems, raises the question of guaranteeing function reliability. That's why dSPACE offers end-to-end expertise in functional safety, test strategy development as well as verification and validation in complex E/E processes - to support you from the earliest project stages to homologation.

dSPACE systems are easy to get up and running – however, if a project is more complex, if individual solutions are needed or if there is high time pressure, you can also trust dSPACE's fast, competent and reliable engineering services.