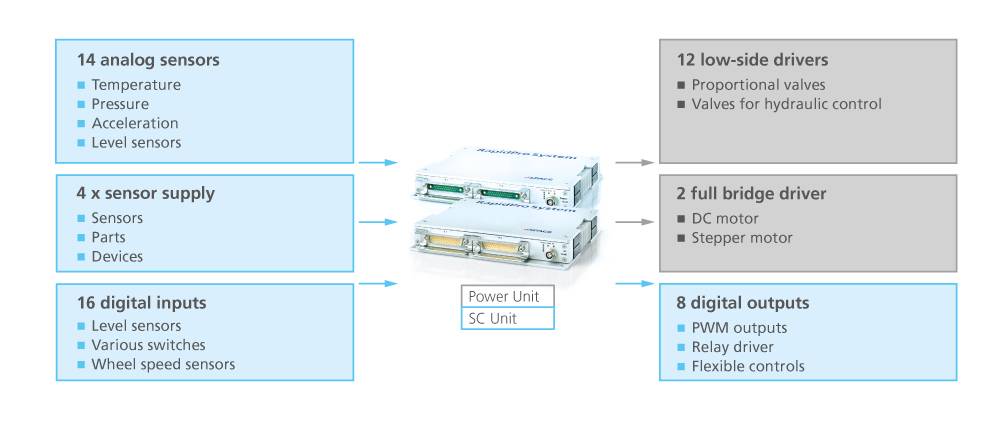

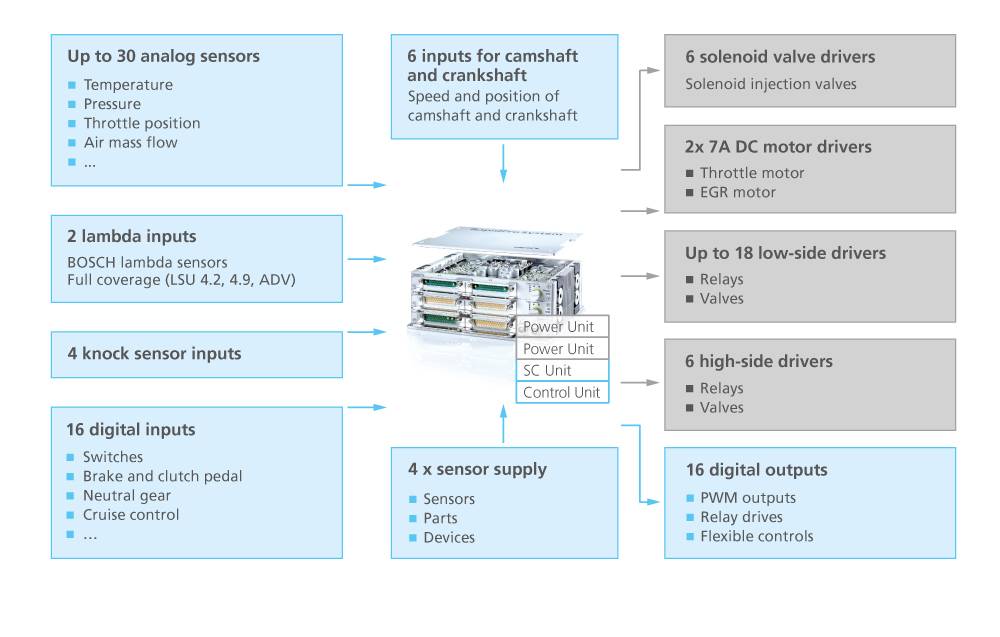

Application-Specific Configurations

For a wide range of typical signal conditioning and power stage tasks in various application areas

- Configurations for control prototyping of engines with up to 6 cylinders and all modern sensors and actuators

- Configuration for electric motor control

- Dedicated Simulink® startup models for the configurations

RapidPro’s predefined configurations cover a wide range of typical signal conditioning and power stage tasks in various application areas. For example, the configurations for engine control prototyping let you run engines with up to 6 cylinders interfacing all modern sensors and actuators, and the configuration for electric motor control serves as a flexible inverter stage during the prototyping phase of diverse AC electric motors. Each configuration consists of selected RapidPro power and signal conditioning modules installed in the corresponding number of RapidPro units. A RapidPro Control Unit is used whenever complex I/O signals need to be captured or generated, or a large number of I/O signals are involved. dSPACE also provides dedicated Simulink® startup models for the configurations. These include all the available I/O signals which are already configured in the corresponding tasks (e.g., angle-synchronous tasks for engine control). This enables a fast startup and lets you concentrate fully on your primary task of developing control algorithms for your application. If your specific I/O requirements differ from the setups, this is no problem at all. You can adapt one of the ready-made configurations or build a new RapidPro system from scratch. Either way, RapidPro will help you solve your specific signal conditioning and power stage task. For further information, please contact dSPACE.

Drive innovation forward. Always on the pulse of technology development.

Subscribe to our expert knowledge. Learn from our successful project examples. Keep up to date on simulation and validation. Subscribe to/manage dSPACE direct and aerospace & defense now.