Electromobility has a lot of potential not only on the road, but also on rail. To tap this market, INTILION GmbH, a specialist in energy storage solutions for lithium-ion technology within the Hoppecke Group, uses a wide range of dSPACE equipment.

When people hear the term electromobility, the first thing that comes to mind is battery-powered electric cars. However, there are also many possible applications off the road, including rail vehicles (Figure 1). Depending on the topology of the powertrain, the battery is used here either as the sole or supplementary energy source. Examples include hybrid drive systems with combustion engines, fuel cells, or emergency systems such as those used in subways to travel to the next station if the main drive fails.

Example Shunting Locomotive: Optimizing Workspace

A conventional diesel shunting locomotive at a freight yard has to accelerate and brake many times a day. However, if it is converted to a hybrid drive consisting of a classic diesel generator and an additional electric motor with battery, there are immense advantages, because in part-load operation only the electric motor works with energy from the battery, and in full-load operation the diesel engine supports the electric motor. In this way, whenever the diesel engine is actually in operation, it always operates in its optimum working range, which significantly reduces fuel consumption, pollutant emissions, and also noise.

Example Mainline Locomotive: Bridging Overhead-Line-Free Routes

Another scenario in which an additional battery-electric drive offers major advantages is a mainline locomotive or railcar on an intercity trip. Because only part of the world’s rail network is electrified, conventional, overhead-line electric locomotives cannot operate everywhere. A diesel locomotive can then be used to bridge the overhead-line-free sections of track, as is the case today, but the better alternative is an electric locomotive that is connected to an overhead line and has an additional battery to bridge the sections of track without an overhead line.

Figure 1: Shunting locomotives (1), track construction vehicles (2), passenger trains (3), and subways (4) are some examples where the use of a battery for rail vehicles is appropriate and brings many advantages, such as lower fuel consumption and reduced pollutant and noise emissions.

Testing the Battery Systems in the Laboratory

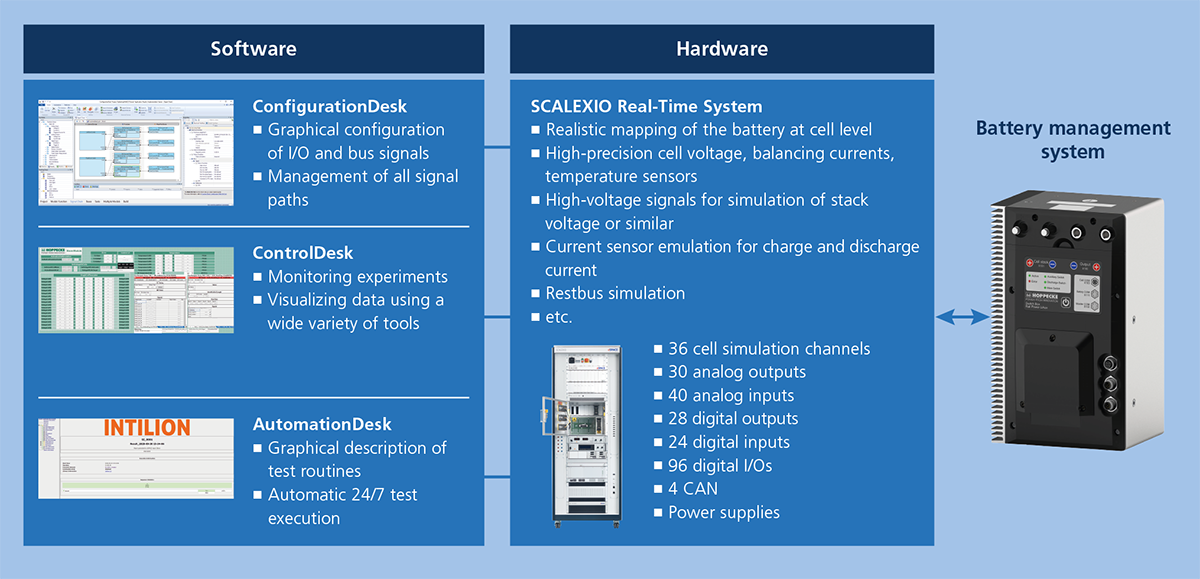

Just as in road vehicles, the battery in rail vehicles consists of a network of often more than a thousand battery cells that are monitored and controlled by a battery management system (state of charge detection, deep discharge protection, overcharge protection, cell balancing, temperature control, etc.). However, the test runs of locomotives on the regular rail network required to test these battery systems under everyday conditions can hardly be conducted in the midst of the closely timed everyday rail traffic. Virtual test drives in the laboratory are therefore the ideal way to simulate everyday situations and thus comprehensively test the battery systems. INTILION uses a system of dSPACE hardware and software (Figure 2) to generate realistic battery voltages, currents, and signals that exactly match those of a real test drive.

Figure 2: A SCALEXIO real-time system generates battery voltages, currents, and signals that correspond to those of a real test drive. This is used to test the battery management system.

Test Environment Based on dSPACE Hardware and Software

The test system was implemented using a dSPACE SCALEXIO real-time system and a dSPACE software tool chain. The commissioning was successfully carried out using dSPACE Automotive Simulation Models (ASM). Due to the open model structure of the ASM libraries, these were easily supplemented later by INTILION’s own models. The battery model was built to generate the typical characteristics of common lithium-ion-based cells (NMC, LTO, LFP, etc.). The connections of the software model to the hardware are configured using dSPACE ConfigurationDesk. The experiment software dSPACE ControlDesk can be used to monitor experiments and test runs, and to visualize any data using a wide range of instruments. During the test runs, the SCALEXIO system generates all the voltages and currents of a real battery system and other signals required for testing the battery management system, for example, bus communication to other control units. The responses of the coupled battery management system are then analyzed. The dSPACE AutomationDesk automation software is used to perform the various tests automatically and in a time-saving manner. Numerous templates from a function library allow the automatic tests to be set up very conveniently.

dSPACE Test Environment According to EN ISO/IEC 17025

The test sequences with the dSPACE test environment meet the standards relevant for railroad applications. These include:

- EN ISO/IEC 17025 (Laboratory management)

- EN 50155 (Electronic equipment on railroad vehicles)

- EN 50126, EN 50128, EN 50129 (Functional safety)

- DIN EN 50657 (Software on rail vehicles)

- EN 50121-3-2 (Electromagnetic compatibility)

- EN ISO/IEC 27001 (IT security)

The internationally important laboratory management standard EN ISO/IEC 17025 is of particular importance. To comply with it, laboratories must be accredited in order to be considered technically competent. For many companies and regulatory authorities, compliance with this standard is a basic requirement for cooperation with laboratories.

Cloud-Based Monitoring of All Batteries

During everyday rail traffic, the battery systems of the locomotives can continuously transmit various operating data via 4G to the Hoppecke Connected Cloud (Figure 3). This data includes the state of charge, operating temperature, number of full cycles, and total energy throughput. This global monitoring of battery systems allows for early fault diagnosis and predictive maintenance of locomotives, minimizing their downtime. In addition, the collected data can also be used to further develop the control algorithms of the battery systems, which can then also increase battery life, among other things.

Figure 3: (a) The locomotives in everyday use can continuously send a variety of battery operating parameters to the Hoppecke Connected Cloud via 4G. (b) The development department uses the received data for the further development of the control algorithms of the battery systems. In the future, adjusted parameters will also be transmitted directly back to the locomotives (dashed arrow).

Second dSPACE Test Bench Ordered

Thanks to the dSPACE development environment, all tests can be completed comprehensively, quickly, and automatically, and in accordance with the norms and standards applicable to railroad applications. Overall, the test bench based on the dSPACE SCALEXIO real-time system provides such good support for testing that INTILION has also equipped the INTILION development center in Shanghai with a test bench. All this boosts the global exchange of know-how (test blocks, Python scripts, etc.) between the INTILION branches, which has once again reduced the effort considerably.

dSPACE MAGAZINE, PUBLISHED JANUARY 2023