Hazardous situations in road traffic can be diverse and complicated. To prepare the newest vehicle generation for as many eventualities as possible, finely tuned test scenarios are needed which come as close as possible to reality, thereby providing test scenarios with a high degree of validity.

Realistic sensor simulations are essential

Innovative applications in the field of advanced driver assistance systems (ADAS) and autonomous driving (AD) are based on signals from individual vehicle sensors. They process these and, in certain circumstances, they actively intervene in the driving process. As the complexity of these functions increases, so do the demands on the technology which then, for example, can only be met with advanced sensor technology.

The current advances in the fields of ADAS and AD would be therefore inconceivable without sensor-realistic simulations. Sensor-realistic simulations enable the exact simulation of vehicle sensors and environments, e.g., for different weather or light conditions, and then give the tester a clear picture of whether the environment and traffic scenarios were correctly captured and evaluated. In this way, ECUs can be tested and validated under realistic conditions, with a variety of relevant test scenarios that can be used in an exactly reproducible manner.

AURELION Connects SIL and HIL Tests

In AURELION, dSPACE has developed a tool that offers the user several advantages at once:

- While software-in-the-loop (SIL) tests can be executed at any speed, hardware-in-the-loop (HIL) tests are performed under exact real-time conditions. AURELION addresses both use cases equally so that, for example, the predevelopment can be started in a SIL environment and the simulation models including all simulation artifacts can then be seamlessly used in the HIL test.

- By scaling the processing power with processor farms or in the cloud, it is possible to execute tests in parallel, thereby executing a high number of tests and their variants, generated by parameter studies, in a manageable amount of time. This is essential for the development of functions for automated driving, as these functions have to be validated with countless test kilometers consisting of safety-relevant scenarios.

- However, realistic synthetic sensor data forms the basis for the development and validation of simulations. Whether lidar, radar, or camera sensors, the more exact the virtual sensor simulation can simulate the real counterpart, the higher the validity of the results. dSPACE therefore maintains long-standing relationships with renowned sensor manufacturers around the world so that their sensor models can be reproduced in the simulation – while respecting IP protection.

- In addition, due to close cooperation, dSPACE has the know-how to feed in the active sensor data which is already at sensor level so that customers can test certain areas of the sensor processing.

With AURELION, relevant hazardous situations can be simulated and visualized extremely close to reality for sensor development.

Test Case Simulation Can Save Lives

The specific example demonstrates how AURELION can be used in the development of radar sensors.

The partners HELLA and dSPACE have jointly set up a simulation solution with which, for example, use cases can be validated in the context of the UNECE 151 - Blind Spot Information System for the Detection of Bicycles regulation. Michael Lemm, Head of System & Software Radar Sensor Simulation, HELLA, explains: “In particular, this is intended to increase the protection of vulnerable road users on the side furthest from the driver. To this end, the trucks are to be equipped with a system to detect and warn them of obstacles in the blind spot (BSIS = Blind Spot Information System).” Possible applications for this include various integration scenarios such as the installation of two sensors at different heights to illuminate the area for which visibility is poor to non-existent.

The requirements for the system are defined in the aforementioned regulation, as are static and dynamic test cases. The static test case illustrates, for example, a traffic light situation, during which a truck stops, and a cyclist approaches the stop line on the right side of the truck. In this case, the regulation stipulates that the driver must be warned for at least 1.4 seconds before the cyclist reaches the front of the truck.

Virtual Coverage of All Scenarios Already During Development

“To develop a BSIS on the basis of radar sensors, the use of radar simulation solutions such as AURELION is useful.” With the help of radar simulation, the aforementioned test case can be implemented very early in the development process,” says Lemm. Different design and development activities can be executed in parallel, without having to use a real sensor. With generic radar simulation models, the influence of various sensor installation positions on the truck with reference to possible sensor illumination can be tested. In this way, the algorithms of the BSIS sensors can be developed with specialized radar simulation models, without a specific prototype being available.

“Furthermore, by coupling a complete vehicle dynamics simulation (ASM), the influence of various truck loads can be taken into account. This is helpful to be able to make statements about the covered ranges even before the real installation in the vehicle. An advantage of AURELION as a simulation solution is that the same simulation models and the same scenarios can be reused in further tests and, in a large number of use cases, implemented up to the homologation/release tests,” comments Lemm.

Curves and straight roads, different semitrailers, and various weather situations can even be taken into account in the simulation and ensure that the subsequent real implementation can be well prepared and comprehensive postprocessing in sensor positioning in the reality can be avoided.

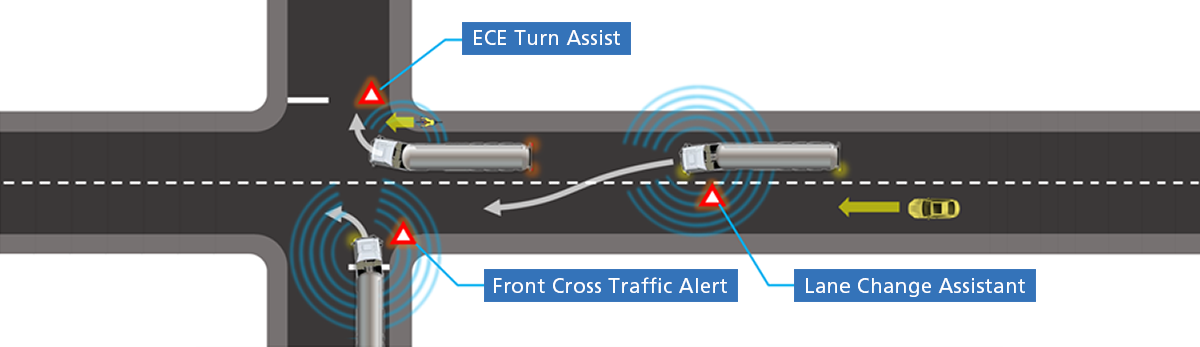

The graphic illustrates various hazardous situations, which can be defused with early sensor recognition.

Exact Simulation to the Millisecond

According to UNECE - 151, blind spot assistance systems have to inform the driver about the potential hazardous situation between the first point of information (FPI) and the last point of information (LPI). The FPI is defined as the earliest possible spatial point at which a potential hazardous situation can be detected and the LPI is the latest possible spatial point at which the system must have informed the driver. These can be precisely simulated in AURELION down to the millisecond. The simulation enables suppliers and OEMs to configure the system in a mutually coordinated manner at an early stage.

Lemm explains: “Thanks to the sensor-realistic simulation in AURELION, we were able to take into account, for example, the usual external influences such as multipath reflections due to construction site situations or peripheral buildings as well as influences in city traffic in a wide variety of variations during the development of our BSIS.”

With the vehicle dynamics model, realistic visualization of tractors and trailers in various curve scenarios is also possible. The dummies required for the homologation can also be simulated in AURELION.

Safer in the Future

Thanks to the UNECE 151 - Blind Spot Information System for the Detection of Bicycles regulation, the streets will become safer for cyclists in the future and serious to fatal accidents will hopefully be a thing of the past. This example shows very clearly how technical innovation and high-precision test scenarios can help the OEMs to further develop the technology and to fulfill this type of requirements.

With kind permission from HELLA

dSPACE MAGAZINE, PUBLISHED JUNE 2023