When developing safety-critical systems for vehicles, automotive manufacturers and suppliers must prove that their processes and tools comply with the relevant functional safety standards. The ISO 26262 standard plays a key role here: Companies that can prove ISO 26262 qualification of their test and development tools also prove that the development was carried out carefully and with a focus on functional safety, in accordance with the current state of the art.

dSPACE Provides Comprehensive ISO 26262 Support

From function development to validation.

For validating ECU software, dSPACE offers several tools that are certified by TÜV SÜD for the development of safety-critical systems according to ISO 26262. All certified dSPACE products thus provide proof of suitability for use in safety-relevant development processes in accordance with ISO 26262:2018 for all automotive safety integrity levels (ASIL).

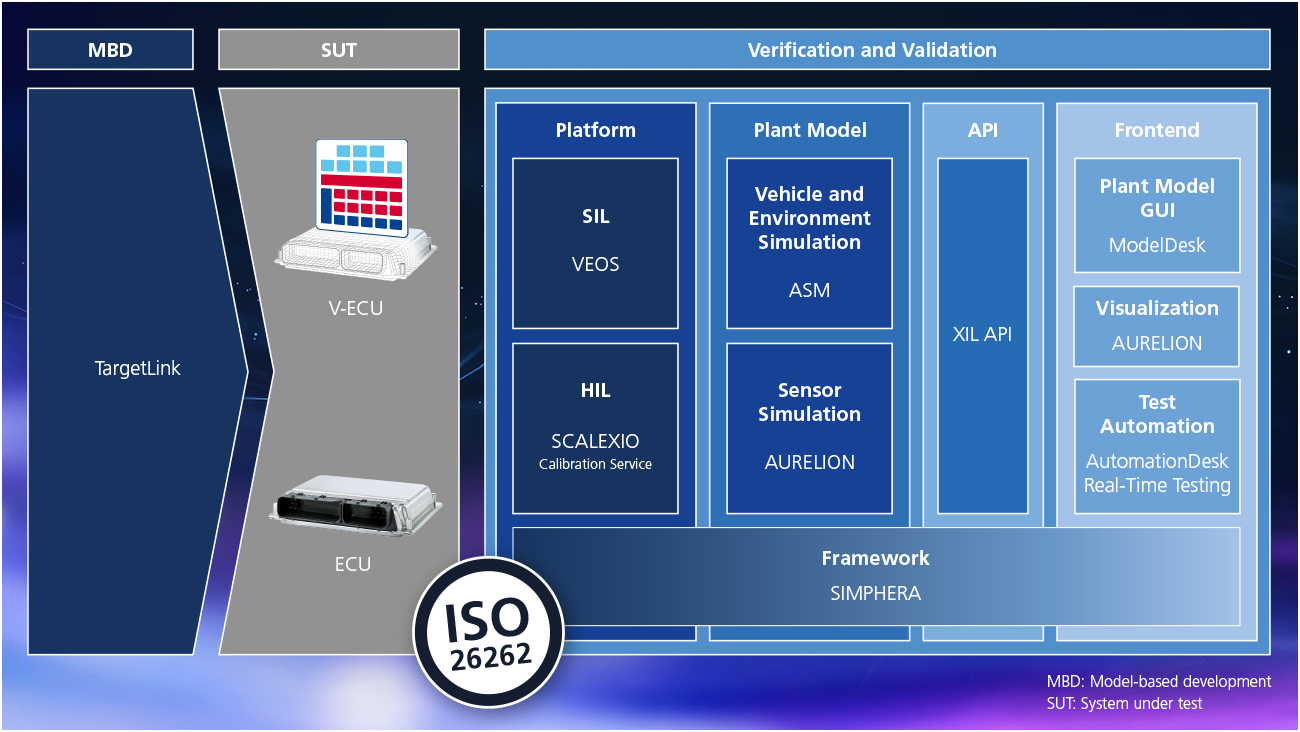

The tools range from function development to validation and include:

- Tools for model-based development and production software development

- A simulation and integration platform

- Simulation models in combination with parameterization and visualization tools

- Test and validation software

As a result, dSPACE customers can rely on a fully certified tool chain for development, simulation, and validation.

Note: The ISO 26262 certification was issued by TÜV SÜD for a specific version of the respective products. Since certification, we have been continuously developing our tools in accordance with the requirements of ISO 26262. As a result, the current product versions are also qualified for the use in ASIL projects up to ASIL D.

More information on the individual tools with ISO certification is available further down this page.

Key Benefits

The certification of the dSPACE products enables users to simplify the qualification of their overall ISO 26262 processes.

For users of the certified dSPACE tools, qualification efforts in safety-critical projects are significantly reduced. In the project-specific safety manual, they only need to refer to tool-specific certificates and corresponding safety manuals provided by dSPACE. This helps our customers concentrate fully on proving the functional safety of their own process chains. They are also provided with safety manuals that support them in their use case.

Furthermore, dSPACE offers consulting services for the management of development and test environments to comply with the standard and implement its requirements efficiently.