Modern electric drives combine high power with perfect control, down to the microsecond. In the development of today’s drives, manufacturers depend on efficient platforms that release these high powers while ensuring operational reliability. To achieve this, JEE uses hardware-in-the-loop (HIL) testing with powerful software modeling and SCALEXIO hardware from dSPACE.

As China’s leading supplier of electric drive systems, JEE advances developments in different fields. These range from individual components to highly integrated solutions that consist of electric motor, converter, and reduction gear. In addition to purely battery-electric systems for industrial vehicles and passenger cars, the focus is also on e-drive systems for plug-in hybrid vehicles (PHEV). According to the ISO 26262 standard, the functional safety of the motor control system must be guaranteed as well. To ensure the required safety and achieve the highest possible efficiency at the development level, JEE adopted dSPACE HIL systems in early development phases for software safety tests and validation on the target hardware.

Multistage Control

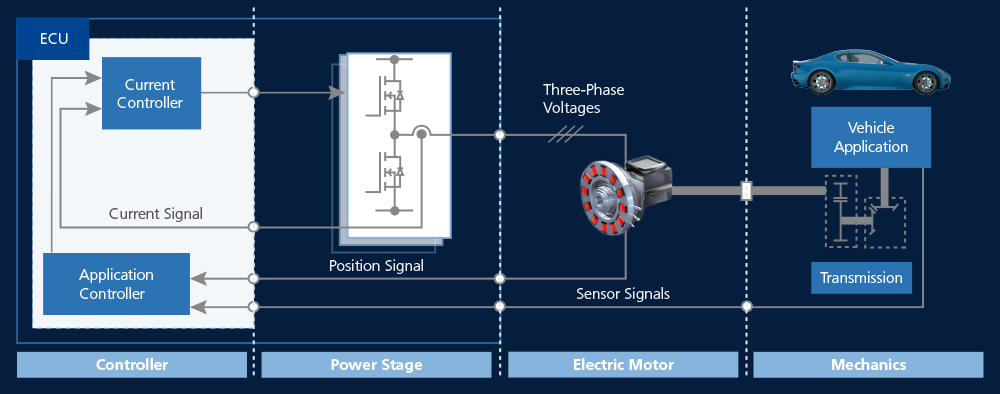

The typical setup of a motor control system consists of a controller and a power module. This powerful system calculates algorithms and converts control signals into three-phase high voltage to drive the electric motor. The torque generated by the motor is transmitted to the drivetrain

Validation System and Design

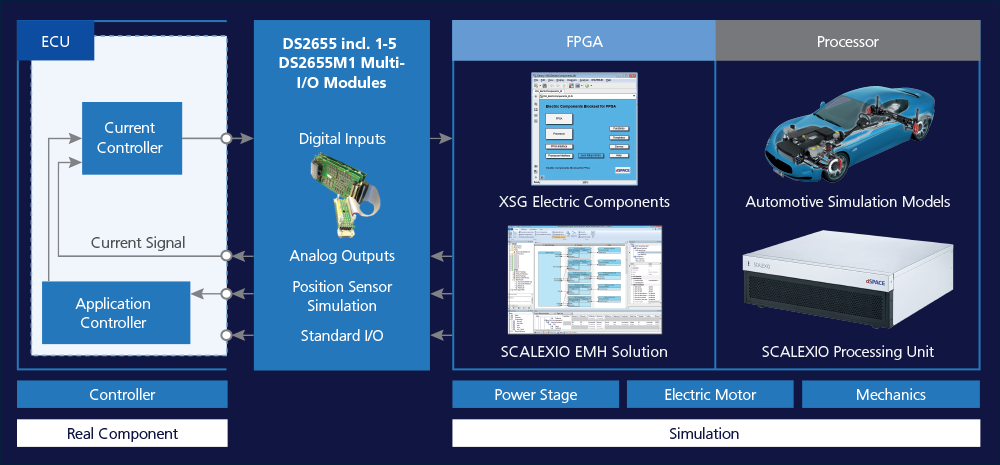

To validate the motor ECU, dSPACE provided JEE with a customized HIL simulation system designed for simulation at the signal level. This means that the actual controller of the ECU is connected to the HIL simulator by- passing the power stages, and only the relevant signals are fed in. The advantage of this process is that the controller can be fully validated without the need to generate the real currents and voltages under laboratory conditions. This not only reduces cost and resource consumption, but is also particularly advantageous for occupational safety, as possible risks from potentially dangerous voltages and currents can be avoided in the test phase.

Models of the HIL Simulator

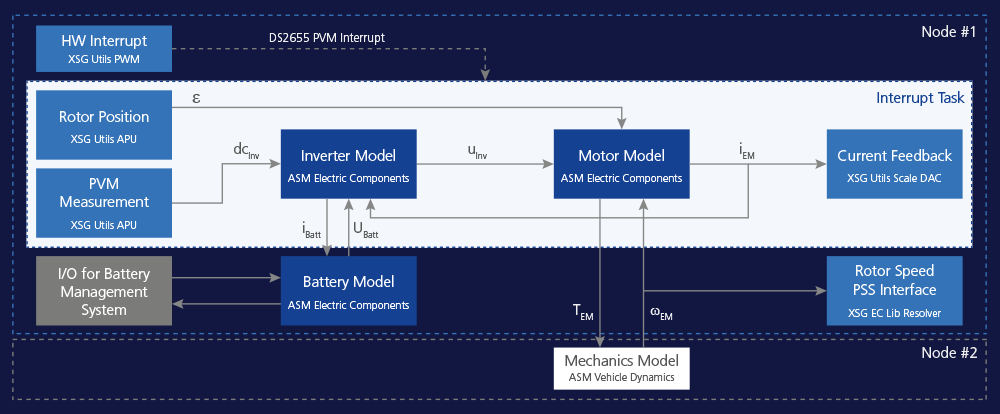

In this HIL system, the model topology is as follows: The simulation model includes an inverter model, motor model, battery model, and the mechanical model. The high dynamics as well as the control properties of the inverter and motor model require high simulation and computation speeds. To meet this requirement, simulation algorithms must be implemented via field programmable gate array (FPGA) chips. The structure of the JEE simulation is therefore divided accordingly: The FPGA part contains models that require fast computation – inverters, motors, and resolvers – while the main processor part contains the less time-critical models, such as the load model.

Open Models Facilitate Adaptation

The software models from the dSPACE XSG Electric Components Library and ASM Electric Components also play a central role. JEE uses the open dSPACE ASM libraries, which simulate entire vehicles or parts, such as asynchronous motors and controllers. JEE also uses the XSG Electric Components Library, which customers can use in conjunction with dSPACE Engineering Services to develop new models. JEE revised the existing asynchronous motor model to develop the controller for an asynchronous motor from it. The modification also made it possible to carry out measurements that were of decisive importance for the success of the overall project, because performing the corresponding tests on a real test bench, which would be the alternative approach, would entail considerable challenges.

Functional Safety

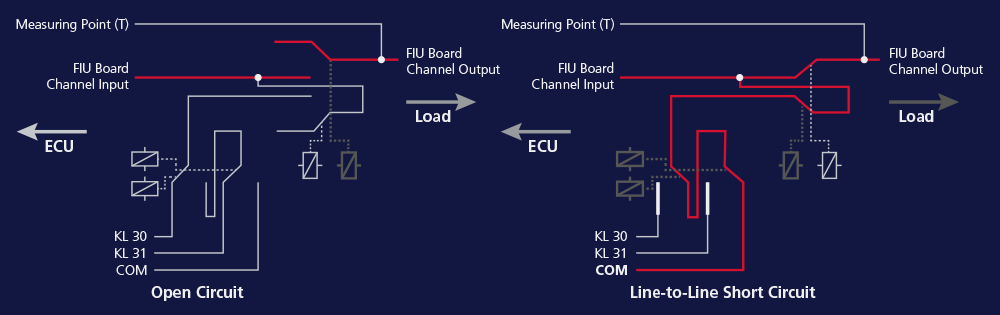

During the development and testing of the motor control system’s functional safety, JEE simulates various faults on the HIL system to test the control strategies for fault diagnosis and fault handling in the control system. The fault diagnosis unit of the Failure Insertion Unit (FIU) in the dSPACE HIL system is mainly used for the ECU wiring harness to test possible faults in the wiring harness, such as short circuits to ground or potential, or between pins, as well as voltage drops. This task is performed by the host PC, which controls the corresponding hardware modules via an RS232 interface. The Failure Insertion Units of dSPACE HIL systems enable JEE to conveniently implement safety-relevant function tests and fault injection. Due to the flexible real-time restbus simulation, this can be done even with incomplete systems. Furthermore, test cases are reproducible and the development cycle can be accelerated.

Test Automation

An important part of HIL tests is test automation. Test automation focuses on the execution of automated, repeatable tests and commissioning based on predefined automation sequences. Under the guidance of dSPACE engineers and with the help of the Python API library in dSPACE ControlDesk, test cases can be programmed to perform more complex test routines. JEE built the HIL test automation platform and created a HIL test case database for various projects, which significantly improved the development efficiency and reusability of test cases.

Results

The extensive use of dSPACE HIL systems from the early development stages to the test phase has significantly accelerated the JEE motor control project. In addition to an efficient increase in the technical maturity level, the operating times on the real test bench were reduced. The HIL system thus improved occupational safety while reducing the necessary resources.

About the authors:

Ying Jiang

Ying Jiang is Senior System Engineer at JEE in Hefei, China.

Ci Zhang

Ci Zhang is R&D supervisor at JEE in Hefei, China.