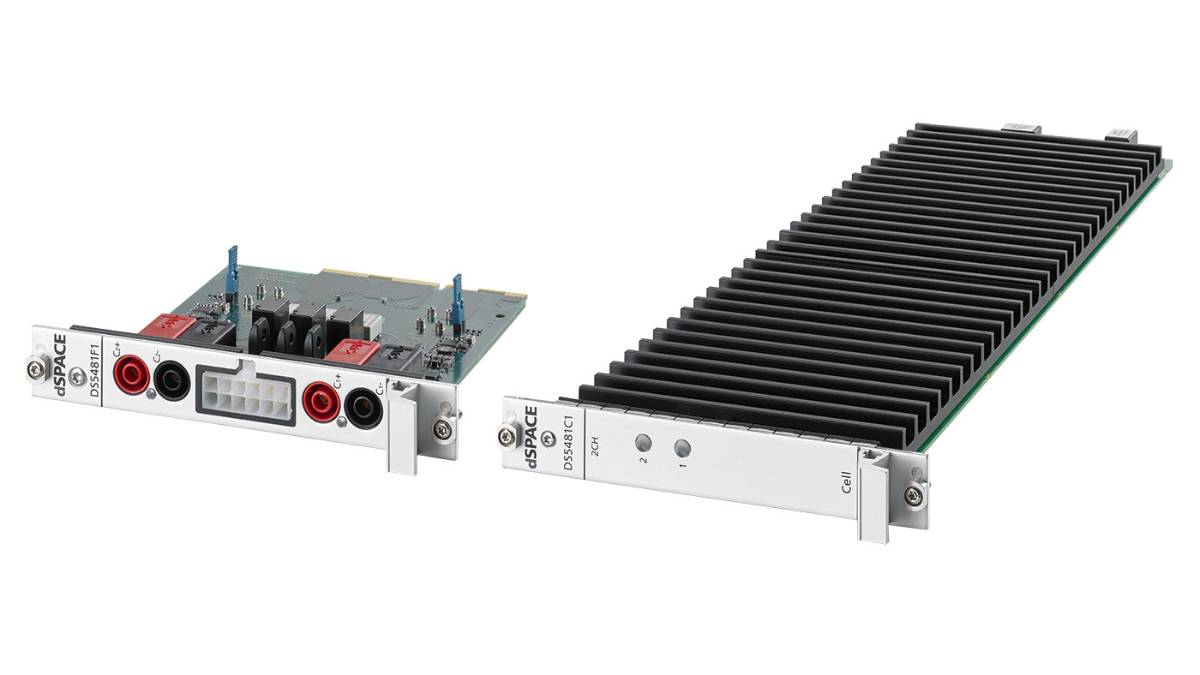

DS5481 Battery Cell Voltage Emulation Board

High-end board for simulating high-voltage batteries at cell level for system voltages of up to 1,500 V

For the HIL testing of cutting-edge battery management systems (BMS) on the voltage level, dSPACE provides the high-precision, two-channel DS5481 Battery Cell Voltage Emulation Board. The board makes it possible to simulate high-voltage batteries at cell level and addresses state-of-the-art and future BMS testing requirements.

- Simulation of high-voltage batteries at cell level with a total voltage of up to 1,500 V

- High-precision cell voltage emulation, current measurement, coulomb counting, and support of cell balancing with high currents

- Integrated electrical failure simulation

Application Areas

Testing battery management systems (BMS) requires the precise emulation of the voltage level of each individual cell of a battery pack.

For testing the BMS used in e-mobility and stationary applications, the high-precision, two-channel DS5481 Battery Cell Voltage Emulation Boards are installed in a slot unit as part of a SCALEXIO Battery HIL system and controlled by a dynamic battery simulation running on the HIL system. These test systems are ideal for testing BMS with system voltages of up to 1,500 V, having advanced requirements regarding balancing currents and precision.

Key Benefits

The DS5481 Battery Cell Voltage Emulation Board emulates controllable, highly-precise terminal voltages for two battery cells, which are internally connected in series. With the support of balancing currents of up to 20 A and an integrated high-precision current measurement and coulomb counting, the DS5481 is specifically designed for applications with high demands on performance and precision. Thanks to the fast and low-latency IOCNET connection, the cell voltages of the DS5481 can be updated with a rate of up to 20 kHz based on a processor application and up to 200 kHz based on an FPGA application. Depending on the simulated battery type and the test focus, several boards can be combined in one or more 19" slot units within a SCALEXIO Battery HIL system.

| Parameter | Specification1) | ||||

|---|---|---|---|---|---|

| Hardware structure |

|

||||

| Output voltage |

|

||||

| Resolution |

|

||||

| Precision2) (for 0 ... 6 V output voltage) |

|

||||

| Maximum current (sink/source) |

|

||||

| Isolation |

|

||||

| Connection |

|

||||

| Maximum update rate for all cells |

|

||||

| Failure simulation |

|

||||

1) Preliminary data. For technical specifications, please contact dSPACE.

2) Limited temperature range.

Cell Emulation Setup

The cell voltage emulation of an entire battery pack is performed using several DS5481 boards. The number of these controllable buffer amplifier boards is configured to match the battery type. The boards supply a continuously adjustable voltage, in the range -6 to 6 V. This relatively wide range means that damaged cells or wrong poling of a battery cell can be emulated. For example, a voltage higher than the nominal voltage simulates a cell's increased internal resistance during charging.

The voltage is output with a precision of up to ±0.3 mV. The voltage is galvanically isolated, allowing the boards to be connected in series up to a maximum system voltage of 1,500 V. Thanks to the fast and low-latency IOCNET connection to the SCALEXIO real-time system, updating the voltages of all cells takes less than 50 µs for processor-based and less than 5 µs for FPGA-based applications.

The maximum current that can be supplied or sunk is 5 A (continuous current) or up to 20 A (peak current), which enables testing of passive and advanced active cell balancing strategies.

- Battery Management Systems Developing and testing battery management systems for electric vehicles

- BMS Testing Solution dSPACE BMS testing provides best-in-class battery cell emulation and real-time-capable battery models for any use case.

Drive innovation forward. Always on the pulse of technology development.

Subscribe to our expert knowledge. Learn from our successful project examples. Keep up to date on simulation and validation. Subscribe to/manage dSPACE direct and aerospace & defense now.