The Task

Before new control units for vehicles are launched on the market, they are tested at various levels. One test step is integration testing, where individual software modules or ECUs are combined and tested as a group – sometimes for individual domains, sometimes even as a complete virtual vehicle.

HIL simulators are established test platforms for integration tests of both individual ECUs and ECU networks. However, as more and more software is used in cars, the software part of the test task is growing and the connections between functions, ECUs, and domains are also increasing. The introduction of a software-in-the-loop (SIL) platform can help drastically shorten development cycles and achieve a faster time to market. What is important is that the test quality is maintained.

Why perform system integration testing in a SIL environment?

For the reasons above, SIL platforms are increasingly being used for integration testing in addition to HIL simulators. These reduce the test focus to software, since no hardware is included.

In turn, they enable massive parallelization of tests in the cloud and access to simulations by different users. For example, the SIL platforms can be used for continuous testing throughout the entire development cycle.

The Challenges

When setting up an integration SIL platform, companies are facing several challenges. Typically, they already rely on different tools in their various development areas and phases, which usually cannot simply be replaced. For the platform, this means that quite different tools, models, and artifacts must be brought together in an overall simulation. However, this approach will also help reuse of artifacts and tests throughout the entire development process.

In addition, it must be possible to move the simulation to the cloud to enable massive parallelization of tests or access by different users. Finally, high test quality and reliable simulation results are key for SIL to add real value to the development and testing process.

The dSPACE Solution for SIL System Integration Testing

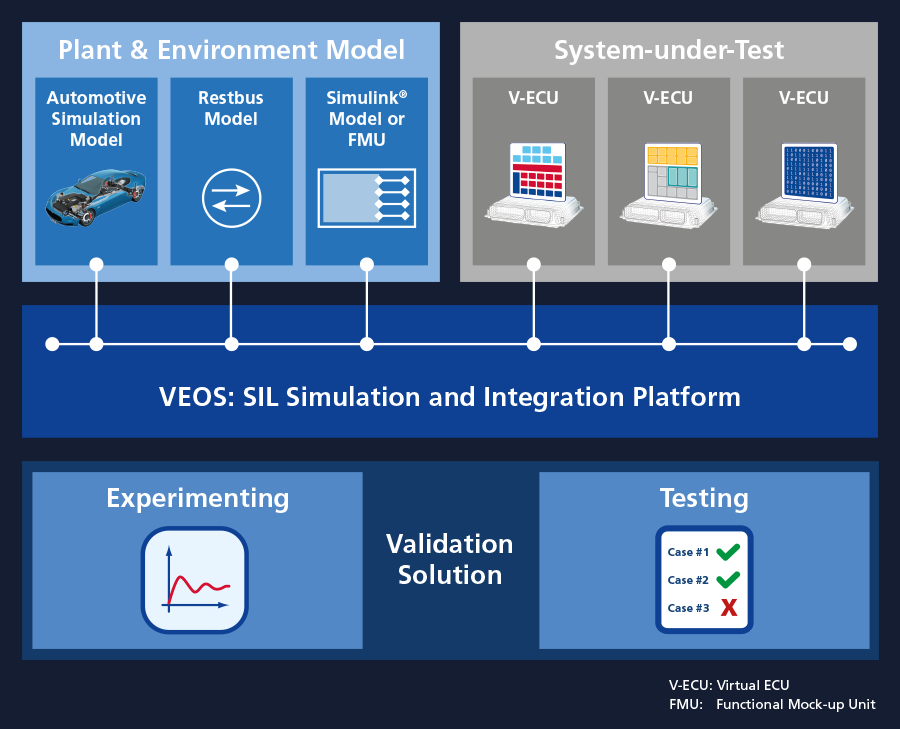

In our simulation and integration platform VEOS, all parts of the simulation system, such as the required simulation models and the system under test, are executed together. With VEOS, dSPACE offers a scalable platform that can be used on different operating systems such as Linux or Windows and is open to integrate all kinds of models, virtual ECUs, and third-party components.

Other components of a functioning SIL platform are the models and V-ECUs to be executed. Existing models and V-ECUs can be integrated into the simulation. If these are not yet available, the dSPACE Automotive Simulation Models provide a comprehensive range of real-time models for vehicle development. dSPACE also supports you in generating V-ECUs, for example with SystemDesk.

Similarly, you can use existing software or dSPACE solutions, when it comes to the validation software for experimenting and testing. This enables you to plan, execute, and automate your tests no matter which test method you use, e.g., requirement- or scenario-based testing. Depending on your needs, you can run single tests or complete test campaigns in parallel in the cloud.

Key Benefits of dSPACE VEOS as a Simulation and Integration Platform

As a simulation and integration platform, VEOS integrates a wide variety of artifacts and tools and connects the various components. It ensures time synchronization and the communication between the different simulation components on the signal and bus levels. The platform also ensures that the simulation results are reproducible – running the simulation again will yield the same results.

VEOS is particularly open and lets you integrate different artifacts and tools into an overall simulation. It supports all relevant standards, such as FMI, XCP, and XIL API. If integration via standards is not sufficient, VEOS can be coupled with third-party tools, such as model simulators or instruction set simulators.

VEOS supports Windows and Linux and can run in the cloud and on local PCs. Automated execution of tests in the cloud allows for the massive parallelization of tests. It is also possible to automate the execution of tests, e.g., in the context of continuous integration processes. VEOS can be used interactively both remotely in the cloud and on a PC – to reproduce errors or to try out new functions.

Watch the Video

At the 2023 dSPACE World Conference, we presented a demo on integration testing with VEOS. This video summarizes the key points of the demo.

See the striking advantages of our dSPACE solution for SIL integration testing at a glance:

- Validate complete vehicles in a SIL environment

- Perform software integration tests for all types of ECUs

- Integrate a wide range of technologies

- Achieve shorter development cycles

dSPACE VEOS: Certified According to ISO 26262

In the development of safety-critical software, it must be demonstrated and documented that the process and tool chains for development, simulation, and validation deliver trustworthy results. To support our customers with this, VEOS is certified by TÜV SÜD for the testing of safety-relevant systems and for the development of safety-critical functions according to ISO 26262. This allows our customers to exclude VEOS from the qualification of their overall processes according to ISO 26262 and to use it in safety-critical projects without any further effort.