Hydrogen fuel cells are becoming increasingly important for vehicle propulsion and energy storage in electric vehicles – especially in trains and commercial vehicles but also in an ever-increasing number of passenger cars. With our solutions, we offer manufacturers all over the world comprehensive support for developing and testing state-of-the-art fuel cell technologies.

Hydrogen Fuel Cells for Stationary Energy Storage Systems

With the transition to renewable energies, the market for stationary energy storage systems is constantly growing. Of course, you can rely on our full support when developing and testing hydrogen fuel cells for stationary applications.

Challenges

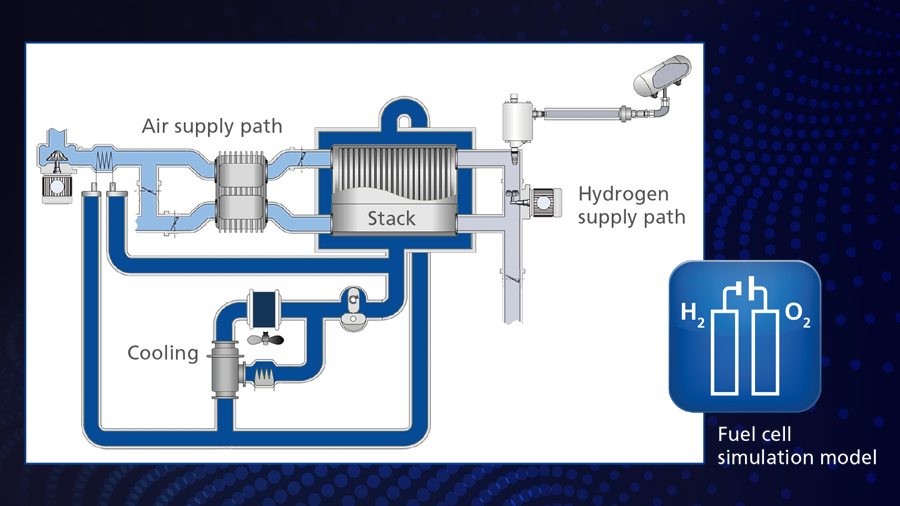

A typical fuel cell system consists of an air supply path (cathode), a hydrogen supply path (anode), and a cooling circuit. To control the operation of the complete fuel cell system, fuel cell vehicles require an electronic control unit (ECU), which has to pass extensive tests before being introduced to the market.

The ECU uses various control algorithms to actuate the components related to the fuel cell system, including hydrogen injection, valves, pumps, and compressors. During ECU tests, the test system must appropriately process the actuation controls. At the same time, the sensor values from the fuel cell system, such as pressure and temperature, must be provided continuously to the ECU. Apart from the testing hardware, this requires mathematical descriptions of the fuel cell system and optionally of the system’s environment. These plant models have to fulfill various requirements, including strong computation performance (real-time capability), scalability, and model accuracy.

Our Solutions for Hydrogen Fuel Cells

We offer the right tools to help you improve your development process of fuel cells and related technologies. Our industry-proven HIL test systems, e.g., based on SCALEXIO technology, include simulators that perform all relevant functions for fuel cell ECU operation. Our ASM portfolio offers suitable fuel cell system models and test environments (e.g., full truck simulation) that can be extended in engineering projects to ensure that you meet all challenges related to the required plant models.

Simulation Modeling

Mathematical models for testing and validating control algorithms by means of simulation

Simulation is an industry-proven method for testing and validating control algorithms and control software. dSPACE offers simulation models that support all stages of development, from function design to ECU testing.

Rapid Prototyping

Production Software Development

TargetLink – production code generation for the highest demands

dSPACE TargetLink generates production code automatically for graphically specified functions straight from MathWorks® Simulink®/Stateflow®. This shortens coding and development times drastically and contributes to a considerable improvement in the quality of the production code.

HIL Testing

One-stop solution for hardware-in-the-loop simulation

As the international market leader for hardware-in-the-loop testing, dSPACE provides the most comprehensive range of tools, solutions, and technology. The dSPACE products and services cover all test phases from function testing to ECU testing to network testing.

SIL Testing

Bus & Network Communication

Simulation and analysis for a wide range of bus systems

dSPACE provides a comprehensive and complete tool chain for simulating, analyzing, and validating networks. In addition to real-time simulation tools and hardware for in-vehicle and in-laboratory use, the dSPACE portfolio includes completely software-based simulation for buses.

Development support from start to finish

Developing complex E/E systems and software with ever more safety-critical functions, especially in the area of autonomous systems, raises the question of guaranteeing function reliability. That's why dSPACE offers end-to-end expertise in functional safety, test strategy development as well as verification and validation in complex E/E processes - to support you from the earliest project stages to homologation.

dSPACE systems are easy to get up and running – however, if a project is more complex, if individual solutions are needed or if there is high time pressure, you can also trust dSPACE's fast, competent and reliable engineering services.