What is HIL Testing?

Hardware-in-the-loop testing means the tests of real ECUs (electronic control units) in a realistic simulated environment. These tests are reproducible and can be automated which leads to 24/7 comprehensive testing in the laboratory, shortens validation times, and increases the range of test scenarios. Additionally testing critical corner cases can be done without creating safety problems for the device-under-test or the environment.

Advantages of HIL Testing

- Test systems scalable from small to large

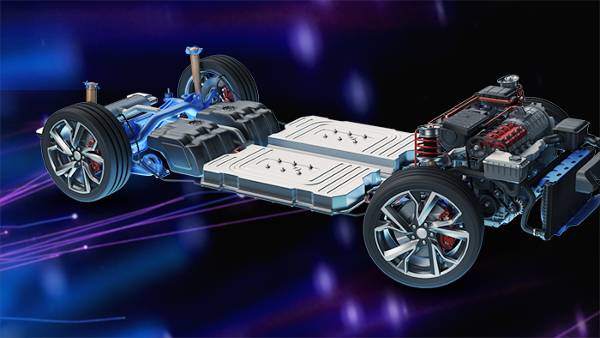

- Simulation of the complete vehicle or integration of real components

- Communication testing

- Bus and restbus simulation

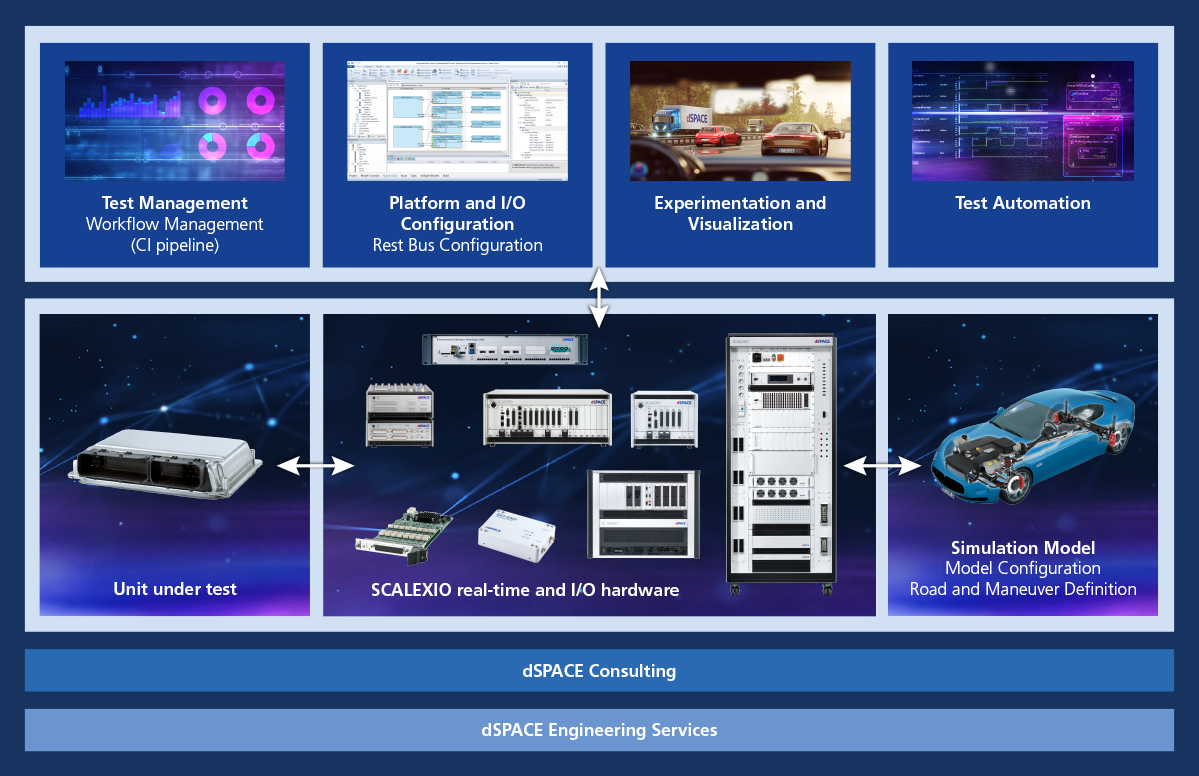

Typical HIL Test System

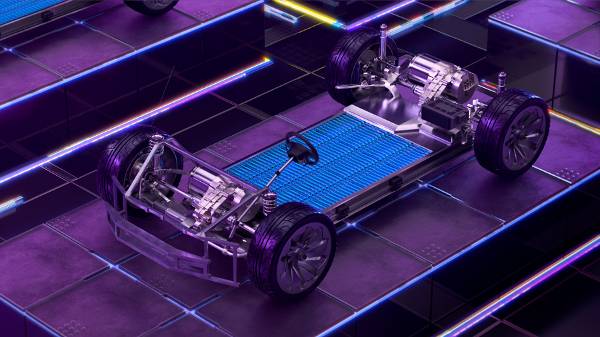

A HIL system comprises of the simulation hardware and the accompanying software. Connected to the system is the unit under test, which usually is one or more electronic control units (ECUs) containing new functions or ECU software to be tested. Depending on the use case, further real hardware components can be added to the test system, e.g., steering or the brake system.

Test Management

Platform and I/O Configuration

Experimentation and Visualization

Test Automation

SCALEXIO Real-Time and I/O Hardware

Simulation Model

Deep Dive – Test Phases and Test Systems in HIL Simulations

Function Testing

Function testing focuses on testing single or a few functions, including their interaction with ECU basic software. Since this kind of testing is typically an integral part of function development rather than final release testing, its focus lies on experimental usage, without systematic test automation. Hardware-in-the-loop (HIL) test systems for function testing therefore require versatile bus and network interfaces, restbus simulation on the behavior and protocol levels, or design-for-test interfaces (e.g., XCP). These types of tests are often performed by the function developers themselves and must fit on a developer’s desk.

ECU Component Testing

Typical applications for ECU tests range from software integration testing through fail-safe and fail-operational testing, to ECU release testing. Testing is therefore highly automated and based on ECU requirements to cover the high number of variants.

Test systems for ECU testing require scalable I/O and bus/network interfaces including electrical failure simulation. Furthermore, testing of buses and networks requires restbus simulation on the behavior and protocol level as well as extensive manipulation.

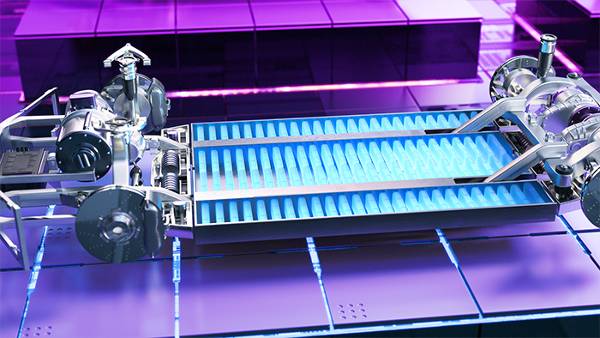

Testing of real components requires comprehensive plant models and simulation performance that can be increased accordingly. Ideally, the test system functions can be adapted to changing project requirements.

ECU Domain and Network Testing

ECU domain and network testing is characterized by end-to-end testing of distributed functions. This includes sleep or wake-up tests as well as fail-safe and fail-operational tests of the vehicle’s ECU network. The need for an extensive range of I/O channels as well as bus and network interfaces is characteristic for these kinds of test systems.

A multitude of plant models must be processed time-synchronously on several clustered real-time systems. To handle complex models and scenarios, strong simulation performance and multiprocessor capabilities are required.

ECU network testing systems often run highly automated test programs around the clock, made possible by comprehensive test management systems.

Application Areas

The dSPACE HIL systems are suitable for a wide range of application areas, from automotive topics to aerospace to railway and marine.