The industry uses a broad range of machines – production robots, packaging machines, bottling systems, and printing machines are just a few typical examples. All of these machines have various kinds of sensors, actuators, drives, and bus systems (e.g., CAN open, EtherCAT), whose interaction only works with the right software.

A general trend is the increasing use of digital twins, which enable virtual commissioning without expensive downtime of the real machine. In new machine development, digital twins also make it possible to develop control algorithms at a time when no real prototype of the machine or tool even exists at all.

In the case of power tools, there is a trend away from classic petrol-powered or corded tools toward cordless battery-powered tools. More battery operation then automatically means a growing need for electric motor control and battery management systems, whose control algorithms need to be developed and optimized.

Challenges

The constraints for the developers of machinery and power tools are manifold. Of course, the perfect functionality of the machine or power tool is always in the foreground, but at the same time, several standards and safety guidelines (including ISO, VDE, TÜV) must be met. In addition, there are also non-functional requirements such as maintainability, expandability, and reusability. In the case of power tools, and especially in the case of hand-held battery-powered power tools, there are additional constraints: size, weight restrictions, battery operation time, disturbing vibrations, changes to spatial position, dirt, etc. Nevertheless, the equipment must work robustly, reliably, and safely in every situation, and at the same time be as compact, quiet, and environmentally friendly as possible.

Our Solutions for Machinery and Power Tools

We offer a comprehensive solution portfolio to bring ideas to life, ranging from controller prototyping, model-based production software development, digital twins for signal-level hardware-in-the-loop (HIL) testing and power HIL testing, to test benches for testing with full power. All solutions interoperate seamlessly to provide an appropriate development and test environment for the complete range of applications. So customers can take advantage from the first controller idea to the final acceptance tests.

Rapid Prototyping

HIL Testing

Central Test Method for Validating ECUs

The dSPACE HIL test systems provide a simulated environment for efficient and reproducible validation of real ECUs in the laboratory 24/7. This increases test coverage and shortens validation times significantly. Our HIL solutions cover all vehicle domains from autonomous driving to zero emissions – starting with component testing and up to virtual vehicle testing.

Bus & Network Communication

Production Software Development

Optimized Production Software Development

The central challenges in production software development include the optimization of RAM resources, run time, and integration into the overall system. Furthermore, it must be possible to split the software in such a way that regular software updates are possible. And before the final software release, special validation and often a release process are required.

Power HIL Testing

Closing the Gap Between HIL and Dynamometer Testing

With our power HIL systems, we offer ready-to-use solutions for testing any kind of inverter, including the controller and power electronics, at full power. Using real voltages and currents, our systems enable you to complete exceptionally rigorous tests. Our systems behave like a digital twin of the real system and allow for easy configuration with just a few clicks, which significantly reduces setup times.

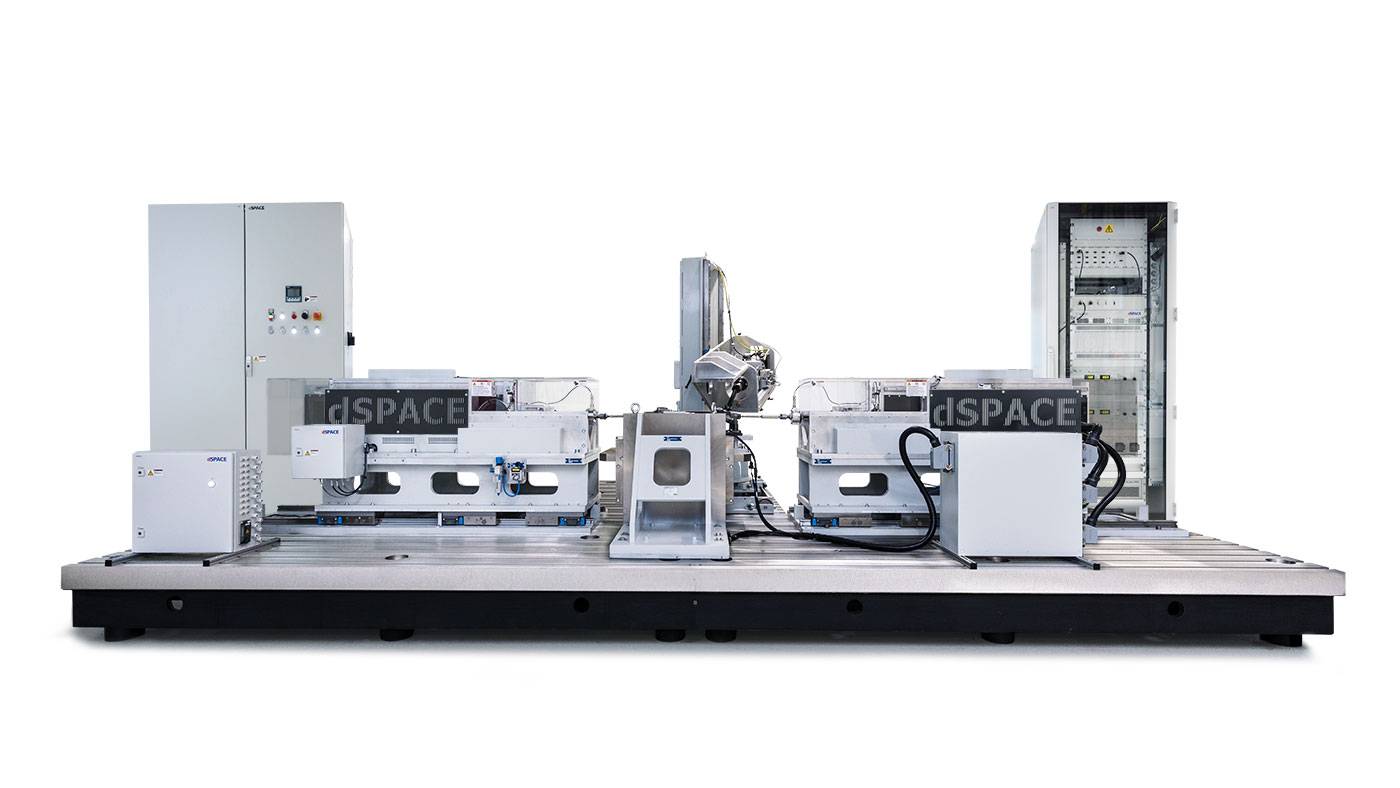

Mechatronic Test Benches

Turn-key solutions – optimally adapted to your requirements

ECUs that cannot be accessed by means of their electrical interfaces can be tested with the highly dynamic dSPACE test benches. The turn-key solutions can be optimally adapted to your specific requirements, letting you use highest performance and most complex control for electric drives providing ideal mechanical interfaces for testing. The mechatronic test benches allow for virtual test-drives including real components in real time, 24 hours a day, 7 days a week.