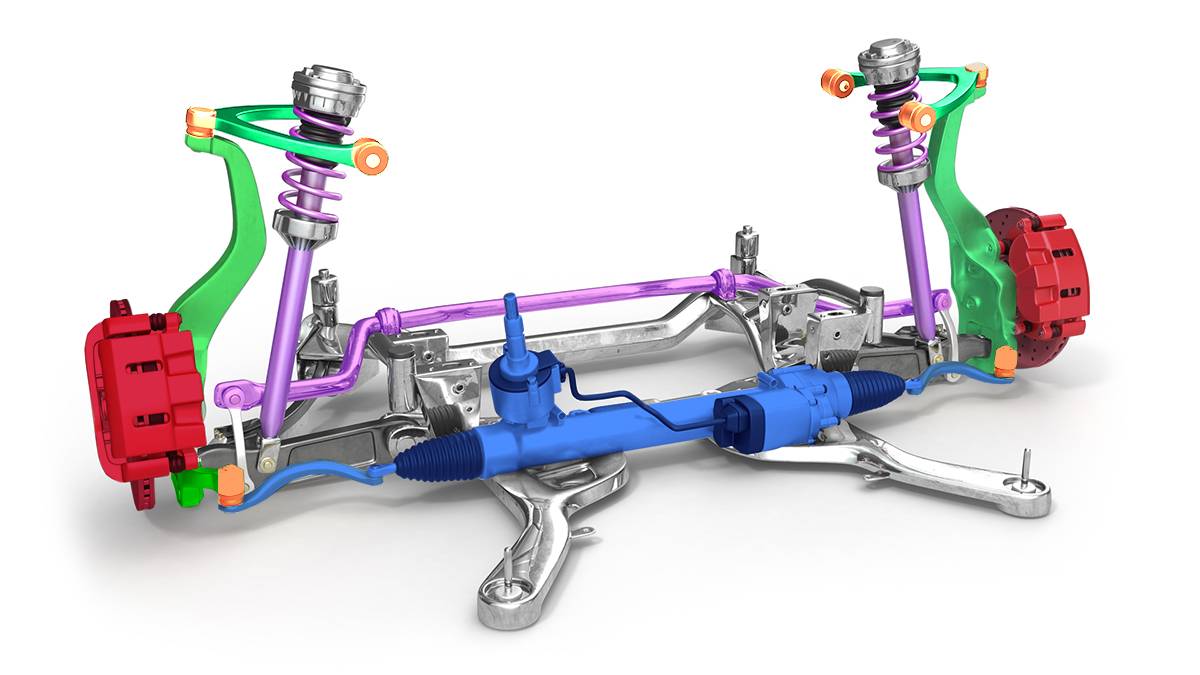

Vehicle dynamics elements, such as wheel suspension, spring and damper, or stabilizers, determine the behavior and performance of a vehicle because they define cornering, dynamics, and comfort, among other things. The wide selection of vehicle types especially for commercial vehicles as well as their modular configuration, which leads to a virtually endless number of variants, poses a challenge for designing and validating vehicle dynamics. Passive and active systems, and different suspension systems such as double wishbone or McPherson strut suspension add even more complexity.

Challenges

Originally developed and tested in test drives, digital product development requires accurate simulation of vehicle dynamics for all conceivable configurations in real time, especially in safety-critical and corner cases. The simulation must also cover the interaction with other vehicle parts, such as brakes and steering, and other general conditions with the same accuracy and at the same time.

Simulation programs therefore use digital vehicle models of varying complexity, for example different truck configurations up to multi-unit road trains with sprung and unsprung masses, complex axle and elastokinematics, elaborate tire models, and other effects to virtually perform defined driving maneuvers. Simulation calculations on longer journeys are intended to help determine factors such as fuel consumption and environmental impact depending on the design of a vehicle and powertrain (engine, gear ratios, shift points, masses, etc.).

Our Solutions for Suspension Systems

For all axle systems, dSPACE provides modular models for kinematics, elastokinematics (compliance), and force elements (spring, dampers, and stabilizers). Depending on the application, the individual systems can also be integrated as active elements in conjunction with a controller (ECU).

Especially for the truck sector, there is the possibility to cover all axle variants with a single simulation model and to change them during a running simulation. This reduces model maintenance to a minimum.

Simulation Modeling

Mechatronic Test Benches

Turn-key solutions – optimally adapted to your requirements

ECUs that cannot be accessed by means of their electrical interfaces can be tested with the highly dynamic dSPACE test benches. The turn-key solutions can be optimally adapted to your specific requirements, letting you use highest performance and most complex control for electric drives providing ideal mechanical interfaces for testing. The mechatronic test benches allow for virtual test-drives including real components in real time, 24 hours a day, 7 days a week.

Rapid Prototyping

Production Software Development

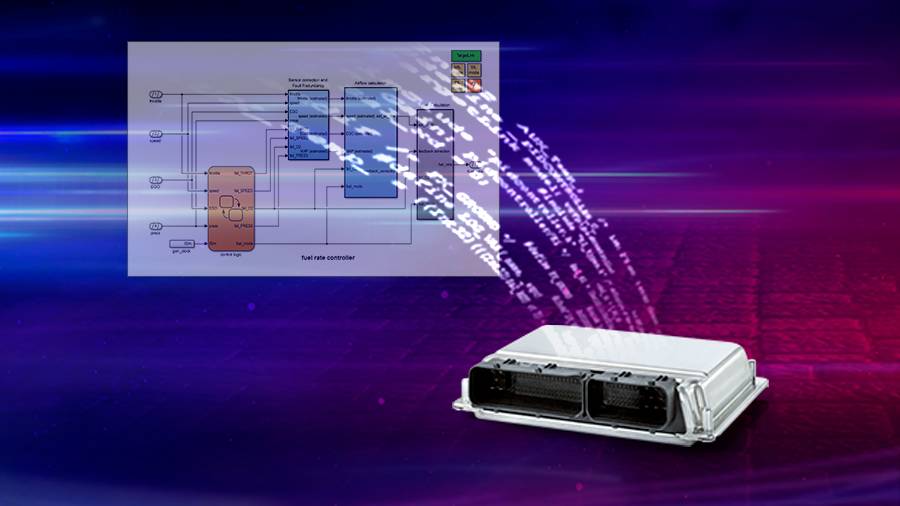

Optimized Production Software Development

The central challenges in production software development include the optimization of RAM resources, run time, and integration into the overall system. Furthermore, it must be possible to split the software in such a way that regular software updates are possible. And before the final software release, special validation and often a release process are required.

SIL Testing

Software-in-the loop (SIL) testing with the powerful dSPACE solution for PC- and cloud-based simulation

With the dSPACE solution for software-in-the loop (SIL) testing, you can significantly accelerate your software development process by testing and validating virtually. dSPACE offers you a complete, modular, scalable development and test solution. You can conveniently simulate a device-under-test on a PC, connect it to physics-based models, run scalable tests in the cloud, and then easily reuse test scripts on hardware-in-the-loop (HIL) systems.

HIL Testing

Central Test Method for Validating ECUs

The dSPACE HIL test systems provide a simulated environment for efficient and reproducible validation of real ECUs in the laboratory 24/7. This increases test coverage and shortens validation times significantly. Our HIL solutions cover all vehicle domains from autonomous driving to zero emissions – starting with component testing and up to virtual vehicle testing.

Development support from start to finish

Developing complex E/E systems and software with ever more safety-critical functions, especially in the area of autonomous systems, raises the question of guaranteeing function reliability. That's why dSPACE offers end-to-end expertise in functional safety, test strategy development as well as verification and validation in complex E/E processes - to support you from the earliest project stages to homologation.

dSPACE systems are easy to get up and running – however, if a project is more complex, if individual solutions are needed or if there is high time pressure, you can also trust dSPACE's fast, competent and reliable engineering services.