What cooperation challenges do we need to overcome?

The automotive industry has progressed rapidly in recent years, with technological innovations changing the way we design, build, and test vehicles. Automotive testing is a crucial aspect of the industry as it ensures safety, reliability, and compliance with industry regulations. However, organizations involved in automotive testing face various challenges that can hinder their progress and affect their overall success.

In this blog, we look at the collaboration challenges faced by organizations involved in automotive testing. In particular, we focus on the challenges of increasing efficiency through test automation and test management. By overcoming these challenges, organizations can improve their testing processes and accelerate the development of high-quality, reliable vehicles.

Manual testing: The basis

Manual testing has been the basis of quality assurance in the automotive industry for decades. Experienced testers carry out various tests, e.g., functional, regression, usability, and performance tests, some of which involve human-controlled interactions with the vehicle's components and systems.

Testers start with test authoring and create detailed test cases based on specifications that are linked to the requirements and use cases to ensure comprehensive test coverage. This is followed by test execution. The testers carry out the tests step-by-step and carefully document the results, including any problems encountered during the tests. In the bug reporting process, the problems are recorded and forwarded to the developers with the relevant information for resolution.

The pros and cons of manual testing

A major advantage of manual testing is flexibility. Manual testing allows for ad hoc investigations and the adjustment of test cases as needed to accommodate changes and evolving requirements. Another advantage is the subjective evaluation. Human testers can rate the user experience and provide valuable feedback on intuitive design and usability. Finally, it is worth mentioning that human testers can also identify visual inconsistencies and aesthetic issues.

On the other hand, manual testing is time-consuming and resource-intensive. Manual testing can be tedious and slow, especially for large projects or regression tests. Manual testing is also prone to human error, potentially overlooking critical bugs or inconsistencies. Furthermore, it may not be possible to test all scenarios manually, resulting in incomplete test coverage.

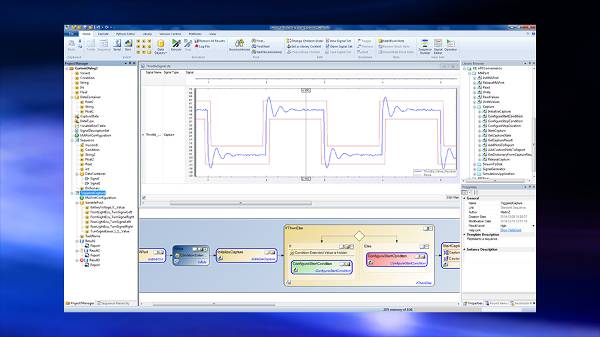

Another advantage is that experienced testers execute test cases accurately, monitor results, and report issues. However, while manual testing provides a deep understanding of the product and its behavior, it is labor-intensive, time-consuming, and prone to human error. For these reasons, more and more companies are now using automation tools such as AutomationDesk in addition to manual testing tools such as ControlDesk.

Switching to automated tests: A paradigm shift

The introduction of automated testing marks a pivotal moment in the testing landscape of automotive companies. Automated testing uses specialized software tools to execute predefined tests automatically and without direct human intervention. The process is more structured and efficient and can be integrated into the continuous integration and delivery (CI/CD) pipeline. The move to automated testing often highlights the need for specialized test expertise.

Automated testing involves the development of test scripts. Test engineers create test scripts using automation frameworks and programming languages to simulate user interactions. Automated tests run repeatedly and consistently, ensuring consistent results and faster test cycles. Automated tests can also be integrated into the development process and trigger tests whenever code changes are made, leading to early error detection.

Increase of speed and efficiency

Automated tests therefore increase the speed and efficiency of the test process. Automated tests accelerate the process by simultaneously executing a large number of test cases, thus saving time and resources. Further advantages are reusability and consistency. Once created, automated test scripts can be reused in different test environments and builds to repeatedly deliver accurate results. Intelligent test automation tools facilitate the reuse of implemented tests through library mechanisms, resulting in a significant reduction in maintenance effort when customization is required.

In addition, automated test execution is independent of human interaction, minimizing the risk of human error, resulting in improved product quality and safety. Test automation that is independent of human interaction promotes continuous integration and testing, enhancing the development pace in agile processes. Automated tests provide safety for frequent code changes and modifications, reducing the likelihood of regression errors and improving overall software quality in the dynamic environment of agile projects.

Finally, while the initial setup of automated testing can be resource-intensive, the long-term benefits far outweigh the costs. Automating tests reduces the need for extensive manual involvement, resulting in significant cost savings over time.

The decision to move from manual to automated testing in the automotive industry will have a significant impact on the efficiency and effectiveness of the quality assurance process. In many cases, a hybrid approach that combines both manual and automated testing could be the ideal solution to leverage the strengths of both methods. Regardless of the approach chosen, adopting automated testing can help automotive companies stay ahead in a rapidly evolving market and also deliver safer, higher-quality vehicles to their customers at a competitive price.

About the author

Ömer Fazil Köroglu

Product Manager, Automated Driving & Software Solutions, dSPACE GmbH